Principal Investigator: Milind V. Khire, Ph.D., P.E.

Research Assistant: Mazen Haydar

Funding Agencies: Waste Management Inc. and Michigan State University

Abstract

Recirculation of leachate in municipal solid waste (MSW) landfills is commonly done for the following reasons:

- Reduce leachate treatment costs;

- Accelerate decomposition of MSW to promote gas generation;

- Accelerate settlement of landfill to gain airspace to dispose more MSW in the landfill; and

- Potentially reduce the post-closure period to reduce the costs associated during the post-closure period.

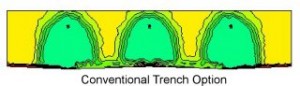

Most commonly used method to recirculated leachate in landfills is using horizontal gravel-filled trenches with a perforated leachate recirculation pipe injecting leachate at a positive pressure. The dimensions of the trench typically are 600 mm wide by 600 mm deep. These trenches are typically laid at 1500 to 3000 m horizontal spacing. Even with such tight spacing, “dry pockets” of MSW where leachate cannot be recirculated are created. These pockets typically exist between the adjacent trenches (Figure 1).

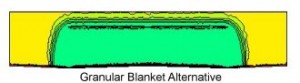

In this research we evaluated an alternative option to recirculate leachate. This option consists of 100 mm to 150 mm thick blanket of granular material (gravel, coarse sand, recycled glass, shredded tires, geocomposite drainage layer etc.) with a perforated pipe installed at the center of the blanket. The advantages of this option include:

- Significantly larger quantities of leachate can be recirculated. Thus, reducing leachate treatment costs and accelerating the settlement of landfill;

- Reduction in number of pipes used for recirculation by increasing the spacing between adjacent pipes;

- Trenching in MSW not necessary to lay the granular blanket. Thus, reducing earthwork costs;

- Reduction of dry pockets in MSW. Thus, reducing differential settlements and hence associated maintenance costs of the final cap; and

- Reduction in average leachate head on the liner.

The saturated/unsaturated flow model HYDRUS2D was used to evaluate the performance of the alternative granular blanket option against the conventional trench option. HYDRUS2D is a 2-D finite-element model developed by U.S. Department of Agriculture. This model solves a modified version of Richard’s equation to model saturated/unsaturated water flow through porous media. Simulations were conducted for the conventional trench and the granular blanket alternative. The boundary conditions were selected such that the leachate head on the liner does not exceed 300 mm. The parameters evaluated from the simulation include:

- Effect of leachate pressure in the injection pipe on the quantity of leachate that can be recirculated.

- Effect of design of leachate collection system on the quantity of leachate that can be recirculated;

- Effect of saturated/unsaturated hydraulic properties of the MSW and the granular material; and

- Effect of the center to center spacing of the conventional leachate trenches versus the area of the granular blanket.

Based on the above evaluations, guidelines are developed for design of leachate recirculation systems for MSW landfills. If you need any further information, please feel free to contact Dr. Khire at khire@egr.msu.edu.

Resulting Publications

- Khire, M.V. and Haydar, M. (2003), “Granular Blankets Alternative for Leachate Recirculation in Municipal Solid Waste Landfills,” Proceedings of the Ninth International Waste Management and Landfill Symposium, Sardinia 2003, Cagliari, Italy, accepted.