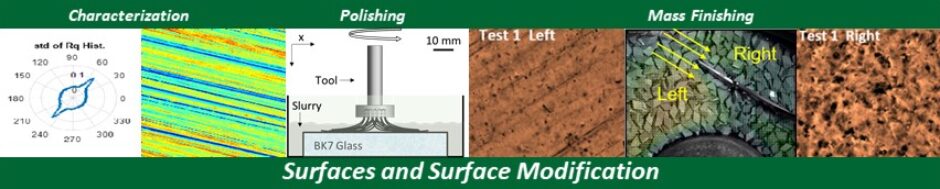

Research focuses on precision surface generation and evaluation. Processes of interest include conventional lapping and polishing, fiber based polishing, and mass finishing processes. Of particular interest is the finishing of freeform surfaces. Advanced surface metrology systems combined with conventional and novel surface quantification approaches are integral in understanding, evaluating and improving surface modification processes.

- Fiber based polishing tools – details (fiber tool)

- Mass finishing of freeform surfaces – Additional details can be found at this YouTube page and here details (vib finish)

- Polar plots for surface characterization and defect detection – details (surface char)

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

High Speed Videos of Vibratory Finishing

Videos referred to in the following paper(s)

- A. Sood,B. Mullany, “Advanced Surface Analysis to Identify Media-Workpiece Contact Modes in a Vibratory Finishing Processes”, Procedia Manufacturing, Volume 53,Pages 155-161, 2021.

- B. Mullany, H. Shahinian, J. Navare, F. Azimi, E. Fleischhauer, P. Tkacik, R. Keanini, “The application of computational fluid dynamics to vibratory finishing processes”, Annals of the CIRP, 66/1/2017, 309-312, 2017.

Sample orientated Normal to the media flow:

Sample orientated Tangential to the media flow: